Laser Marking Systems / Laser Markers

Laser Drilling

Laser drilling is a process that uses a laser beam to create precise holes in a variety of materials across industries like automotive, semiconductor, food/beverage, medical devices, and electric vehicles. Within these industries, laser-drilled holes are utilised for a range of processing goals.

Laser drilling processing examples:

- Air holes on packaging

- Holes for fasteners to connect to

- Screw holes

- PCB holes

- Lens holes

- Solar Cells

Drilling is known as being done with needles or punch tools. However, needles and punch tools can be inefficient and tedious. Punch tools and needles are handheld or achieved by a machine requiring manual production. The production line moves slower than the automated style of laser drilling. Moreover, not only is the manual process tedious, but drilling this way can cause accidental errors or cause breakage in the rest of the part. Using punch tools and needles applies force to the whole component, which causes breakage or weakening.

Additionally, inaccurate results can occur from tool wear/degradation. Mitigating that risk requires preventative maintenance measures such as coolant, cleaning, and spare tooling. These measures all bear additional cost with a compounding concern of production downtime. Laser drilling in comparison is a consumable free operation with assured repeatable performance.

Laser drilling utilises an extremely thin and precise laser beam, offering a non-contact, highly repeatable method of attaining these holes. It only hits the target point without any aftershock to the rest of the material. It’s optimal for all drilling needs—from sensitive materials like film to strong materials like metal.

Laser drilling is particularly useful in industries with sensitive products, like the medical device and semiconductor industries. These industries are known to have parts that are easily breakable, very small or thin, or have especially harmful consequences if contaminated.

Basic Principles of Drilling Using Laser Markers

Contrary to the name, laser drilling does not need a specific laser drilling machine. Laser drilling can be achieved by using a laser marking machine. Laser markers work at high speed and specialise in all processing needs like cutting, marking, welding, and, of course, drilling. Using a laser marker for drilling eliminates all physical tools, extra consumable items, and time for adjustment.

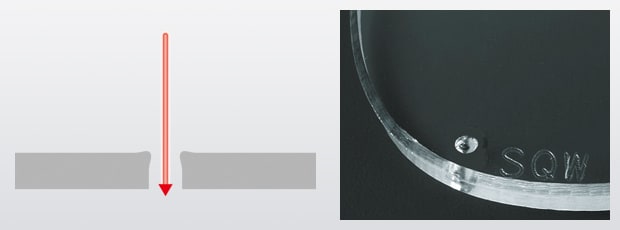

Drilling a hole in a lens

Laser drilling uses laser light to melt/evaporate a single point on a target. It doesn’t add force that exerts on the rest of the component. It's vital to choose the right laser wavelength and output power best suited for the target material in order to achieve high-accuracy processing.

Laser Drilling Machines

KEYENCE’s laser marking machines are automated, consistent, and precise for laser drilling. The laser markers have a patented 3-Axis control making them robust and repeatable over different materials, focal distances, and surface height changes.

They can be programmed to laser drill into a variety of shapes and sizes, including 2D and 3D shapes like steps, cylinders, inclined surfaces, and circular cones. If a product does not fit that scope, the laser markers can use 3D CAD data to find a target on a complex profile.

Laser markers are fully automated to review errors that would otherwise slow down production time. They contain autofocus, automatic adjustment depending on size or material, an inspection of their own lens, and the ability to diagnose marking errors to ensure accuracy and uniformity.

3-Axis CO2 Laser Marker ML-Z Series

KEYENCE's 3-Axis CO2 Laser system uses a concentrated beam to carefully drill into a wide variety of materials. CO2 lasers work by generating heat in order to melt or vaporise layers of material. By directing the beam at a fixed point, they wood, rubber, ceramics, and glass.

KEYENCE even offers a model of the ML-Z Series that features a shortened wavelength and smaller beam spot, allowing for micro drilling of holes and making it ideal for any transparent materials.

3-Axis Hybrid Laser Marker MD-X Series

The 3-Axis Hybrid Laser Marker MD-X Series is a combination of a fibre laser and a YVO4 laser. It combines the two strengths of each laser. Fibre lasers are designed for long service life and high output. YVO4 lasers are designed for high quality and depth of focus. Together, these lasers create the MD-X with high peak power and a short pulse laser. The MD-X uses a 200 kW peak power with a frequency of 4 ns. The 200 kW peak power is around 20x that of what is achieved by conventional fibre lasers. Even a fibre laser system that offers a substantially higher "average power" will not be able to generate nearly as high of a "peak" power which is far more important for absorption in any drilling or processing application.

The high peak power and short pulse laser result in minimal heat damage while still quickly and precisely drilling through a vast array of materials. Laser drilling may need precise yet deep drills, which MD-X can do with its deep depth of focus.

Contact KEYENCE for a Free Demo

Tired of manual drilling processes and slow production? Looking for an alternative to conventional drilling? Unsure which laser drilling machine is best for your manufacturing and industry goals? Contact KEYENCE , and our team will get back to you quickly! We offer a free demo of our CO2 and Hybrid laser machines for your laser drilling needs. Once you decide, we have your back with technical, onsite, and after-sales support.