Observation and Measurement of Coating Using a Digital Microscope

The process of adding new functionality to relatively thin base materials (targets) such as films, sheets, steel plates, or glass is also called “converting.” In general, this is done through coating actions such as chemical agent coating, deposition, and sputtering. Functionalisation is used in a wide range of fields, such as for touch panel electrodes for smartphones and tablets, thin film coating on LCD glass, and precision pattern coating on electronic PCBs. This section introduces coating observation and measurement examples using a digital microscope.

- Difference between plating and coating

- Purposes of coating

- Coating types

- Coating observation/measurement examples using a digital microscope

Difference between plating and coating

- Plating

- Electroplating is when a conductive metal surface is coated with a different material. This is perhaps the most common method for coating a material with metal. Other methods include chemical plating, which uses chemical reactions; molten plating, which uses immersion in molten metal; and vapor deposition plating, which uses a metal vapor spray.

- Coating

- Coating makes it possible to create a film layer on both conductive and non-conductive surfaces. Plating can also be thought of as one coating type.

Purposes of coating

- Functionalisation

- Coating can be used to increase the functionality of a base material (target) such as by improving adhesion, wettability, water repellency, corrosion resistance, heat resistance, and wear resistance.

- Surface processing

- Surface processing is used to optimise the surface of a base material by coating it with a chemical agent. One example is the hydrophobic treatment of semiconductor wafers using a chemical agent before the resist coating process.

- Decoration (design)

- Coating is often used to improve the appearance (design) of a target.

Coating types

- Dry coating

- Dry coating is a generic term for the technique that coats a "solid" material for functionalisation of the base material. Typical coating methods include vacuum deposition, ion plating, and sputtering. Dry coating is used for coating metal materials and allows high-quality deposition without the need for a drying process. The disadvantages are the larger size of equipment, limitations on continuous production, and higher costs.

- Wet coating

- The wet coating technique is commonly used in a wide range of industrial fields. The material for functionalisation is "liquefied" through the process of dissolving or dispersion into a medium. The liquefied material is uniformly applied to the base material and then dried or cured to be converted into a solid film. When it is necessary to avoid adhesion of dust or foreign particles onto the liquid film, wet coating is performed in a clean room. Unlike dry coating, this method does not require a vacuum environment but instead can be done in an atmospheric environment. A wide selection of equipment is available, and the target (base material) can be fed continuously. Because wet coating provides numerous advantages in high-volume production, it has been adopted widely in various coating systems.

Coating observation/measurement examples using a digital microscope

The latest examples of coating observation and measurement using KEYENCE’s VHX Series 4K Digital Microscope are introduced below.

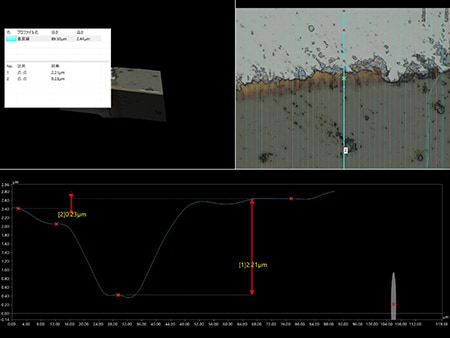

HDR allows for visualisation of defects.

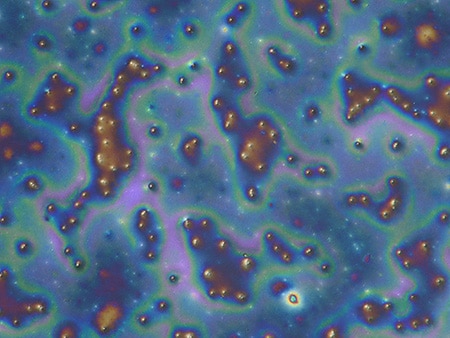

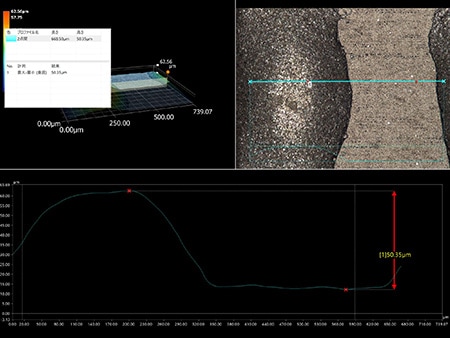

Optical Shadow Effect Mode (colour mapping) image

Optical Shadow Effect Mode allows for visualisation of surface irregularities.

VH-Z20, 200×, coaxial illumination

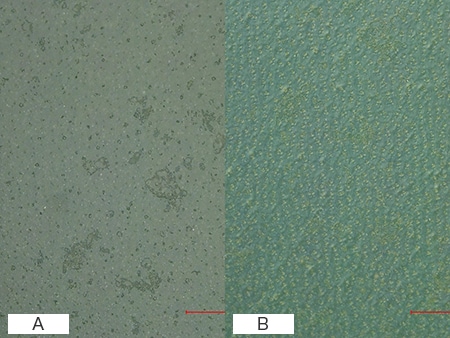

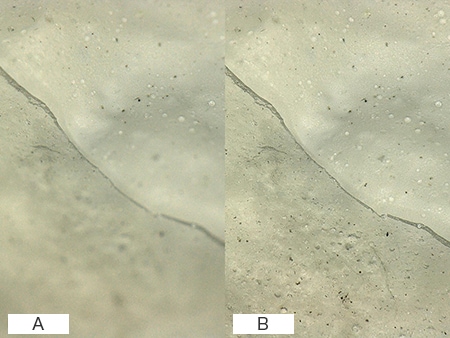

- A: Normal image

- B: Differential Interference Contrast (DIC) + HDR image

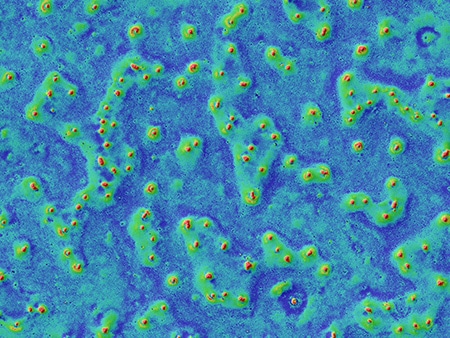

Differential Interference Contrast (DIC) and HDR allow for visualisation of uneven applications.

VH-Z20, 100×, ring illumination

- A: Normal image

- B: Depth composition image

Observation of transparent coating is also possible.

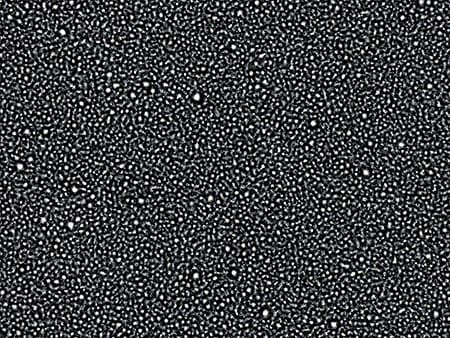

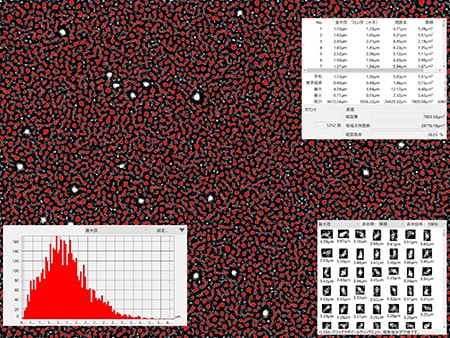

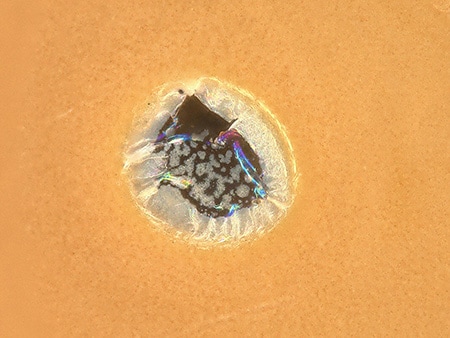

Automatic area measurement allows for quantification of coating particle variations.

Foreign particles were confirmed inside the coating material.