[Manufacturing Industry] Automobiles/Transport Equipment

Typical handheld mobile computer usage examples were explained in “Handheld Mobile Computer System Installation Applications,” but this section introduces actual application examples regarding automobiles/transport equipment in the manufacturing industry. Actual examples will be used to explain the problems in various processes at manufacturing sites for automobiles/transport equipment and the advantages provided by installing handheld mobile computers in said sites.

- Manufacturing of Automobiles/Transport Equipment

- Problems in Manufacturing of Automobiles/Transport Equipment

- Solving Problems by Installing Handheld Mobile Computers

- Typical Processes and Manufacturing Flow

- Advantages Provided by Installing Handheld Mobile Computers in Various Processes

- Improving Operation With Character Recognition Handheld Mobile Computers

Manufacturing of Automobiles/Transport Equipment

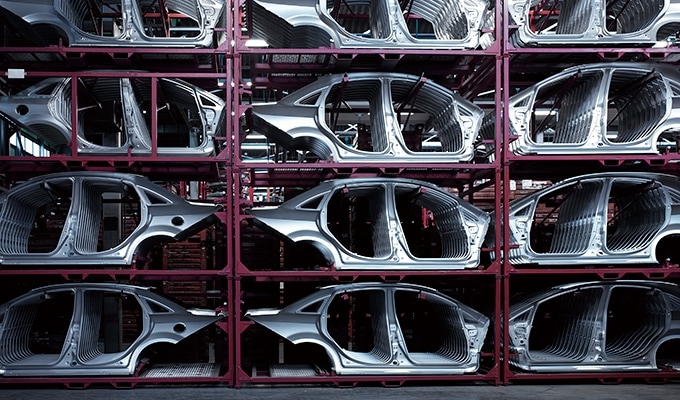

High quality and accuracy are required in the manufacturing of automobiles/transport equipment: a minor defect may lead to a major accident. For example, including small bolts, it is said that an automobile is made of over 30 thousand parts, and this count continues to grow as automobiles become more and more multifunctional. It is extremely difficult to inspect these parts perfectly and manage their information.

Furthermore, if an automobile/transport equipment recall occurs, it is necessary to immediately identify and collect all the affected products. In recent years, End-of-life Vehicle Recycling Law has also been enacted, which has led to requirements for traceability not only at manufacturers of completed vehicles but also at part manufacturers and car dealerships. To meet all these needs, there are limits to what people can physically do. Hence, in addition to the automation of manufacturing processes, the automation of information management with a handheld mobile computer system installed is key.

Problems in Manufacturing of Automobiles/Transport Equipment

Production schedule delays directly affect delivery dates in manufacturing industries. This is not a problem that is limited just to the manufacturing of automobiles/transport equipment. The main cause is careless management of processes and inventory. While it is obvious that careless process management will lead to delays, careless inventory management such as mistakes in inspection and shelving during reception of materials will cause picking errors and thereby affect the manufacturing process schedule. If there are problems in inventory management, it will not be possible to accurately manage the manufacturing process, which will inevitably lead to an increase in waste in postprocessing.

Solving Problems by Installing Handheld Mobile Computers

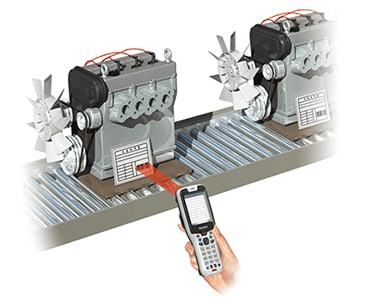

If handheld mobile computers are used to perform management with barcodes/2D codes right from reception, the manufacturing process situation and the process work history data can be collected and made into a database immediately, which makes it possible to determine in real time what products are in what processes and are in what sort of semi-finished state. Who is performing what work and how long they are taking to do so can all be managed in a centralised manner, which improves efficiency by enabling accurate estimates of delivery dates and flexible assignment of personnel.

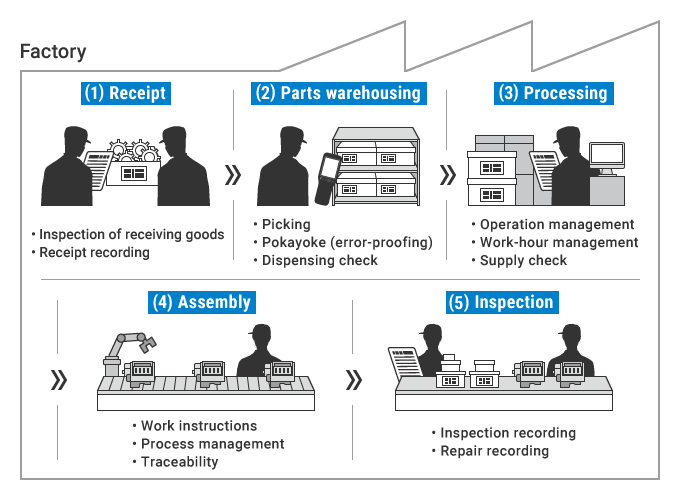

Typical Processes and Manufacturing Flow

This section explains detailed handheld mobile computer installation examples grouped by process during the manufacturing of automobiles/transport equipment. The typical processes and manufacturing flow for automobiles/transport equipment are shown below.

Supplier

- Finished product warehouse

-

- Shipping inspection

- Inventory management

- Inventory

Advantages Provided by Installing Handheld Mobile Computers in Various Processes

This section explains the advantages of installing handheld mobile computers and actual application examples for the typical processes listed above.

Parts receiving

Installing handheld mobile computers makes it possible to read barcodes and similar items provided with parts and immediately convert the receiving information into data, which prevents careless mistakes caused by visual inspections. When parts are used on a manufacturing line, inventory is moved automatically, which eliminates the recording and data entry performed by personnel, thereby enabling correct inventory management. This greatly improves the accuracy of the inspection of receiving goods/incoming inspections.

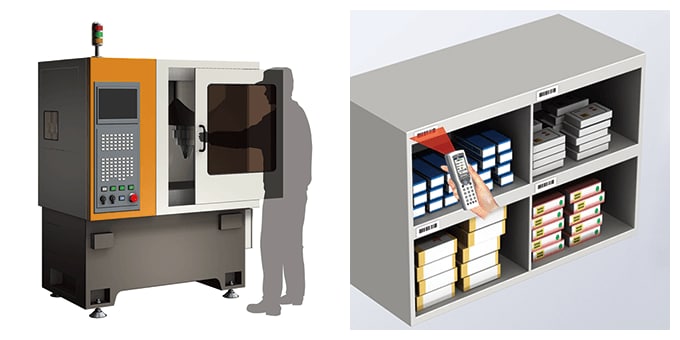

Parts warehousing

If mistakes occur in visual inspections during warehousing, confusion will arise during the picking of the parts required for the manufacturing line, and the subsequent processes will be greatly delayed. Also, the dispensing process, in which parts are lined up in the order in which work is performed, will also be thrown off. By using handheld mobile computers and barcodes to associate product information with shelf information, this work can be made faster and more accurate. This enables accurate picking work, efficient inventory management, and major improvements in the speed of verification work.

Processing

Handheld mobile computers can be used to perform overall operation management, work-hour management, insertion checks, and tool management in real time, which makes it easy to manage the progress of processes. In turn, this can be expected to lead to improved product quality. In addition to information on parts and products, the usage situation and consumption situation of consumables, equipment, and tools can also be determined, which is effective in the preventative maintenance in equipment management.

Assembly

Assembly mistakes are the typical problem that can happen easily in this process. Handheld mobile computers can be used to check parts and to show the work procedure on the display just by scanning the codes on products and parts, thereby creating an assembly environment that anyone can understand easily. It is easy to mistake parts and products that have similar product numbers and shapes, but assembly mistakes can be reduced by performing management with items such as barcodes. In addition, the work record can be obtained automatically, which is effective for traceability.

Inspection

One of the advantages of installing handheld mobile computers is that integration with the system makes it possible to simplify the registration of product serial numbers. Product traceability is also dramatically improved, so it is possible to immediately identify the process that was the cause of problems such as defective workpieces. Inspection results and repair results are converted to data on the spot, which makes it clear how to work toward quality improvements.

Finished product warehouse

Finished products are brought into the company's warehouse where they wait for delivery. Erroneous shipments can be greatly reduced by performing shipping inspections that do not rely on visual checks. Also, handheld mobile computers can be integrated with the system to improve the efficiency of inventory management and inventory counting.

Improving Operation With Character Recognition Handheld Mobile Computers

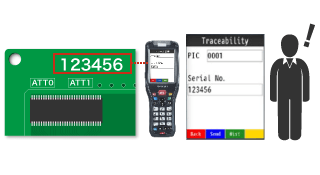

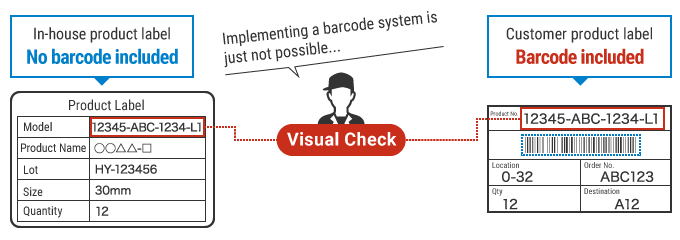

Serial numbers and lot numbers are sometimes not converted to barcodes at automobile/transport equipment manufacturing worksites. In this situation, it was necessary to rely on visual inspections. However, using handheld mobile computers that support optical character recognition (OCR) enables accurate and fast work and is effective in eliminating mistakes and improving work efficiency. KEYENCE's BT Series of handheld mobile computers supports optical character recognition (OCR), so these devices are very effective in situations such as that shown below.

Verifying product slips and products

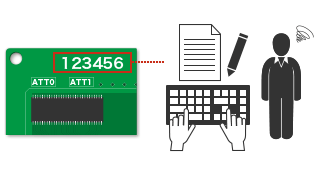

Up to now, it was a hassle to handle character strings such as the serial numbers on part labels. For example, operators had to check the character strings visually, write them down by hand, and manually enter them into a PC. What's more, a lot of the data is very similar, so mistakes often occurred with visual inspections. With handheld mobile computers, all the operator has to do is scan the character string to enter it into the system, so mistakes caused by visual inspections can be greatly reduced and work can be optimised.

Conventional

- Visual check, handwritten record, and manual entry into a PC

Improvement

- Just scan the serial number to easily enter it into the system.

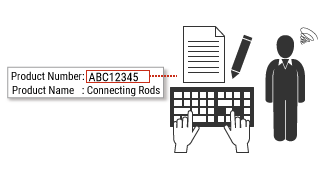

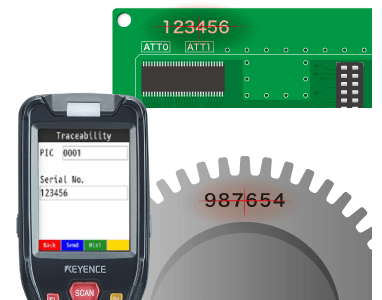

Tracing products and parts

When serial numbers and lot numbers are marked directly on PCBs and metal, the characters are very small and may be difficult to read depending on the material, which are problems. However, it is often the case that barcodes cannot be marked due to the material or the available space. Conventionally, this information was checked visually, but this led to noticeable mistakes arising from parts of the text not being read or being read incorrectly and from the handwritten records and manual entry into PCs. By installing handheld mobile computers, operators only have to scan the text to enter it into the system, which leads to better tracing of products and parts on which barcodes cannot be marked.

Conventional

- Visual check, handwritten record, and manual entry into a PC

Improvement

- Just scan the serial number to easily enter it into the system.