Inventory management

The change in manufacturing from production of large lots of a narrow variety of products to production of small lots of a wide variety of products has led to an increase in the hassle involved in inventory management. This is a major problem not only for the manufacturing industry but also for the logistics industry, which transports products, and the retail industry, which sells products to consumers. The key items used in solving this problem are barcodes, 2D codes, and handheld mobile computers. This section introduces items such as basic knowledge pertaining to inventory management, the flow for installing handheld mobile computers, the way to use handheld mobile computers, and the advantages of doing so.

- What Is Inventory Management?

- Inventory Management Methods and Problems

- Operation With Handheld Mobile Computers

- Advantages Provided by Handheld Mobile Computers

What Is Inventory Management?

Inventory management refers to maintaining the optimal number of items to match the situation. “Items” refers not only to products but also to raw materials, parts, tools, equipment, and anything else that has monetary value. Inventory management is vital in running a business and can be separated into stock management and inventory.

- Stock management

- This refers to clarifying the location, quantity, and status of items and managing factors such as the list of items and the quantities of items with actual objects and ledger data. Inventory management as people generally imagine it is close to this stock management. The purpose is to ensure that the quantity of items in stock is always appropriate: never too high or too low.

- Inventory

- This refers to products, works in process, semi-processed products, raw materials, consumables, and any other such expendable assets consumed in sales activities and general administrative activities. Prices are evaluated through the performing of inventory as assets used in the acquisition of revenue, so inventory management also includes optimising the quantity and status of inventory.

Inventory Management Methods and Problems

The basics of inventory management are the securing of a storage location and the appropriate management of inventory by strictly keeping items organised, orderly, clean, and sanitary. To put it simply, inventory management refers to clarifying the location and status of stored items. Normally, numbers are assigned to the shelves, rows, and levels in the storage location to enable the determination of where items are stored. The warehousing of items in storage locations is recorded in ledgers. This sounds easy, but problems such as items not being where they should be and differences between the ledger data and the actual quantities occur in practice. The following issues are possible causes for these problems.

- Details such as the types and quantities of products are not recorded correctly at the worksite.

- The entry of information is missed or is performed mistakenly during warehousing management.

- Operations such as the taking out of items and the moving of items from one storage location to another are not managed.

- Items are managed poorly, resulting in damage and loss.

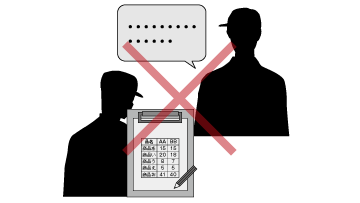

The majority of the above issues are problems in the management mechanisms and organisations or are user-caused errors. In inventory management, when moving an item, it is important to move the item's slip as a set with the item and to record the movement in the ledger data, but these tasks are difficult to carry out perfectly at busy worksites. Especially with the low volume, high mix production that is performed these days, entering data by hand is a hassle and poses major risks of operators forgetting to enter data or entering it incorrectly.

Operation With Handheld Mobile Computers

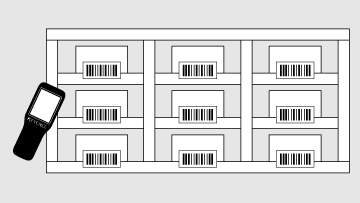

As described above, there are limits to what can be done by having operators enter ledger data manually. When there are many things subject to inventory management, it is effective to use an inventory management system in which barcodes and 2D codes are affixed to items and handheld mobile computers or similar devices are put to use.

First, read the barcodes for the item and its location (shelf, row, and level), and then enter information such as the quantity to register it. If location management has not been performed, generate barcodes and affix them to the shelves or similar locations. After all the items and locations have been registered, accurate stock management can be performed just by reading the barcodes during warehousing and when moving items. The data from operations such as warehousing and inventory can be checked in real time, which enables appropriate management.

- Use handheld mobile computers to perform inventory.

-

Handheld mobile computer

- Send the acquired data to a PC.

-

Communication

- Data management with a PC

-

PC

Advantages Provided by Handheld Mobile Computers

This section introduces the advantages of performing inventory management with handheld mobile computers. Installing handheld mobile computers can greatly reduce the conventional hassle of inventory management and is effective in improving work efficiency. Furthermore, unnecessary inventory can be reduced, which shrinks costs and strengthens business structures.

Easy location management

Location management is easy. This eliminates the problems of picking taking a long time, operators not knowing where to place inventory, and the locations for inventory being known only by certain people. Reading a barcode/2D code with a handheld mobile computer clarifies the shelf number, row number, and level number, so all operators can determine locations in the same manner, which improves efficiency.

Enables first in, first out management

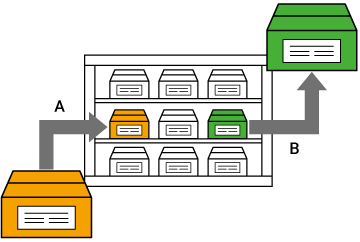

- A: First in

- B: First out

With handheld mobile computers, it is possible to also record the date with the read barcode data. Caution is required for issues such as food and medicine exceeding their expiration dates and best-before dates, but handheld mobile computers can be used to easily perform first in, first out management, which was conventionally a hassle to perform. Other advantages include preventing the shipment of products that have exceeded their best-before dates before it happens by setting alerts according to dates and being able to read best-before dates marked with characters by using handheld mobile computers that support OCR.

Also supports lending management

The management of items frequently lent within the company—such as equipment, measuring instruments, and tools—was very difficult. However, affixing barcode labels to these items makes it easy to perform lending management and to verify their locations.

Reduces the load of inventory work

Conventional inventory work was inefficient: two people would work in a pair with one person reading the data and the other person recording it. However, handheld mobile computers eliminate the work of entering data, so one person can perform accurate inventory work. All the operator has to do is read barcodes and enter quantities, so knowledge of the products is also unnecessary. Furthermore, there is no need to enter data into a PC, which eliminates issues such as operators entering the data incorrectly.