[Manufacturing Industry] Electrical/Electronic Devices and Semiconductors

This section introduces actual application examples regarding electrical/electronic devices and semiconductors in the manufacturing industry. Actual examples will be used to explain the problems in various electrical/electronic device and semiconductor processes and the advantages provided by installing handheld mobile computers.

- Electrical/Electronic Device and Semiconductor Manufacturing

- Problems in Electrical/Electronic Device and Semiconductor Manufacturing

- Solving Problems by Installing Handheld Mobile Computers

- Typical Processes and Manufacturing Flow

- Advantages Provided by Installing Handheld Mobile Computers in Various Processes

- Improving Operation With Character Recognition Handheld Mobile Computers

Electrical/Electronic Device and Semiconductor Manufacturing

Smartphones, video game consoles, PCs, and other consumer electronics are becoming more and more compact and thin. Consequently, there are needs for greater precision in the manufacturing and inspection processes of electrical/electronic devices and semiconductors. As the integration of electronic devices and semiconductors into other devices continues, the diversification of needs has made production of small lots of a wide variety of products and cell production common, which has led to an increase in the hassle and cost of part management and inspection.

For microscopic parts such as IC chips, resistors, capacitors, and transistors, it is difficult to mark the product number on each individual part and to visually perform difference checks, so it is easy to take the wrong part. The diversification of needs has also led to an increase in the number of similar products, and the product cycle is becoming shorter, which has increased the hassle involved in product management. Hence, handheld mobile computers are used in operations such as management of parts and products.

Problems in Electrical/Electronic Device and Semiconductor Manufacturing

Manufacturing sites of electrical products, electronic devices, and semiconductors deal with various problems including machine trouble and part material shortfalls/defects. No matter how careful operators are, it is not possible to eliminate the occurrences of production delays caused by these problems, so it is important to create systems for detecting and immediately recovering from problems. Therefore, it is necessary to identify the on-site situation in real time.

Furthermore, to improve manufacturing costs, it is necessary to accurately determine the time required for manufacturing and other work. Hence, production management and result collection are said to be the keys to manufacturing worksite improvement. Handheld mobile computers are used as a solution for these problems.

Solving Problems by Installing Handheld Mobile Computers

In recent years, the cellular manufacturing has become commonly used as the production method at electronic device manufacturing worksites. In this production method, the assembly of a wide variety of products is handled by one person or a small group of people, so it is necessary to handle detailed work instructions and the supply of parts in an ad hoc manner. With handheld mobile computers, operators can check the work instructions and the inventory status of the required parts for each product just by scanning barcodes, which is very efficient. Handheld mobile computers are also used in many other processes.

For example, as a general statement regarding manufacturing worksites, it is important to develop the correct production plan and carry out production according to said plan. However, if the inventories of raw materials, parts, works in process, and finished products cannot be determined accurately, it is not possible to develop an accurate schedule. Especially if shortfalls occur, not only the production site but the materials warehouse and the shipping section are all thrown into chaos, and it becomes impossible to fulfil the expected process and quantity.

There are no problems if the inventory is managed correctly with ledgers, but due to factors such as mistakes in the information written on slips and careless mistakes, there is no guarantee that the recorded information accurately reflects the actual inventory. Regarding this point, handheld mobile computers can be used to achieve mistake-free inventory management just by scanning barcodes and product slips. This makes it possible to identify the accurate quantity and storage location of products at all times and immediately replenish parts even if a shortfall occurs. Installing handheld mobile computers in this manner makes each process efficient and also makes the overall production operation healthy.

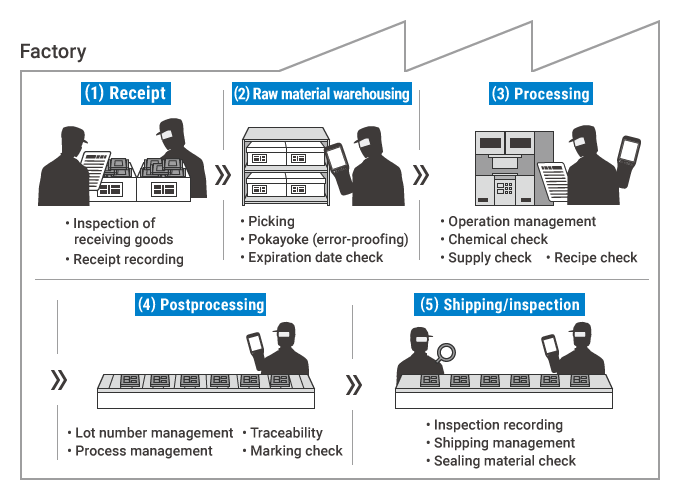

Typical Processes and Manufacturing Flow

This section explains detailed handheld mobile computer installation examples grouped by process during the manufacturing of electrical/electronic devices and semiconductors. The typical processes and manufacturing flow for electrical/electronic devices and semiconductors are shown below.

Supplier

- Finished product warehouse

-

- Shipping inspection

- Inventory management

- Inventory

Advantages Provided by Installing Handheld Mobile Computers in Various Processes

This section explains the advantages of installing handheld mobile computers and actual application examples for the typical processes listed above.

Receiving

When checking slips visually, no matter how careful the operator is, reading mistakes occur at a certain rate. However, using handheld mobile computers makes it possible to nearly eliminate mistakes by reading barcodes and similar provided information. The receiving results can be immediately converted to data, which eliminates the hassle of having to enter the data manually at a later time.

Also, when handheld mobile computers are used on a manufacturing line, inventory is moved automatically, which eliminates the recording and data entry performed by personnel, thereby enabling correct inventory management. This greatly improves the accuracy of the inspection of receiving goods/incoming inspections.

Raw material warehousing

If mistakes occur in visual inspections during warehousing, confusion will arise during the picking of the parts, and great losses will occur in the subsequent manufacturing processes. By using handheld mobile computers and barcodes to associate product information with shelf information, work can be made faster and more accurate such as by realising accurate picking work, making inventory management more efficient, and increasing the speed of verification work. Also, handheld mobile computers generate warnings when raw materials have exceeded their expiration dates, which prevents these materials from being supplied to the worksite by mistake.

Preprocessing

Preprocessing consists of processing and manufacturing processes such as raw material blending and machining, surface processing, and exposure processing. Problems occurring during this preprocessing greatly affects the postprocessing and the delivered product. Handheld mobile computers can be installed to perform overall operation management, chemical checks, insertion checks, and recipe checks in real time, which makes it possible to handle problems as soon as they occur, thereby preventing delays in postprocessing.

In addition to information on parts and products, the usage situation and consumption situation of consumables, equipment, and tools can also be determined by handheld mobile computers, which is effective in the preventative maintenance in equipment management.

Postprocessing

Postprocessing indicates mounting and assembly processes such as soldering. Typical problems include assembly mistakes and solder defects. During cellular manufacturing, the operators handle multiple parts, so it is easy for mistakes to occur. However, installing handheld mobile computers makes it easy to check the work procedure and the parts. Just by scanning the codes on products and parts, the work procedure is shown on the display. This saves time and effort and prevents mistakes. Lot number management, process management, and traceability can also be made more efficient.

Shipping/inspection

Installing handheld mobile computers enables integration with the system and makes it possible to automate the registration of product serial numbers. Inventory management can also be simplified, which also increases the shipping and inspection speed. Furthermore, product traceability is dramatically improved by installing handheld mobile computers, so it is possible to immediately identify the process that was the cause of problems such as defective workpieces. Moreover, inspection results are converted to data on the spot, which makes it clear how to work toward quality improvements.

Finished product warehouse

Finished products wait in the company's warehouse for delivery. Erroneous shipments can be greatly reduced by performing shipping inspections that do not rely on visual checks. Also, handheld mobile computers can be integrated with the system to improve the efficiency of inventory management and inventory counting.

Improving Operation With Character Recognition Handheld Mobile Computers

Serial numbers and lot numbers are sometimes not converted to barcodes at electrical/electronic device and semiconductor manufacturing worksites. In this situation, it was necessary to rely on visual inspections. Typical examples of items for which visual inspections are required include serial numbers, lot numbers, and device data. Switching from these visual inspections to handheld mobile computers that support optical character recognition (OCR) enables accurate and fast work and is effective in eliminating mistakes and improving work efficiency. KEYENCE's BT Series of handheld mobile computers supports optical character recognition (OCR), so these devices are very effective in situations such as that shown below.

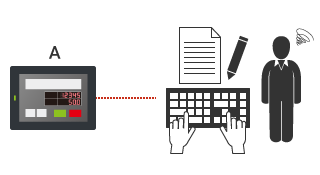

Work instructions and device data verification

Devices made by various manufacturers are used at manufacturing worksites. Handheld mobile computers that support optical character recognition (OCR) can also be used to read the seven-segment characters displayed on devices. The mistakes caused by visual inspections do not occur and the process of visually inspecting the target, writing the results by hand, and manually entering the results into a PC can be completed just by scanning the target, so this makes work more efficient and thereby enables accurate data management.

Conventional

- Visual check, handwritten record, and manual entry into a PC

-

A: Touch panel

Improvement

- Just scan the serial number to easily enter it into the system.

-

A: Touch panel