- Home

- Solutions

- Case Studies

- Zero Downtime Saves Company from Headaches

Zero Downtime Saves Company from Headaches

Background

A material handling company uses a large automated conveyor system to transport trays of parts among each of many process stations. The process stations typically involve high heat environments.

The Problem

The automated tray loader will occasionally load a tray improperly on the conveyor track. This misloaded tray eventually crashes the production line creating downtime, machine damage and potential danger for operators.

An improperly loaded tray can be derailed on either side of the conveyor track. When looking from the side of the conveyor system, a derailed tray appears either too far from or too close to the conveyor's edge. A properly loaded tray is at the accurate distance from the edge.

As a side note, the trays are sintered in the process stations and therefore appear somewhat multicolored.

The Solution

KEYENCE's GV distance-based sensors work well to detect improperly loaded trays. The GV is mounted to look at the side of each tray as it passes on the conveyor. A properly seated tray passes at the accurate distance from the sensor head whereas an improperly loaded tray passes either too close to or too far from the sensor. The GV, set in area mode, reliably detects either of the two problem situations and alerts operators to the situation before the misloaded tray can crash the production line.

As a side note, the GV's distance based sensing overcomes what is normally a sensing nightmare - multicolored targets. The discoloration on the trays caused by repeated heating and cooling is not an issue.

The Results

The GV solves this application and eliminates headaches for the customer. Without the GV, this application would require a "measurement" type solution at approximately 10 times the cost.

Related Products

-

- Digital CMOS Laser Sensor

GV series -

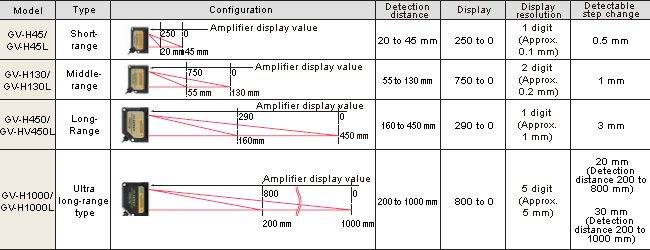

The NEW GV Series Digital CMOS Laser Sensor provides unmatched performance, even on metal and black (rubber) targets. Multiple models available to meet all your laser sensing needs.

- Digital CMOS Laser Sensor

- PLEASE

CONTACT US