- Home

- Solutions

- Case Studies

- High-Speed Inspection of Broken Biscuits

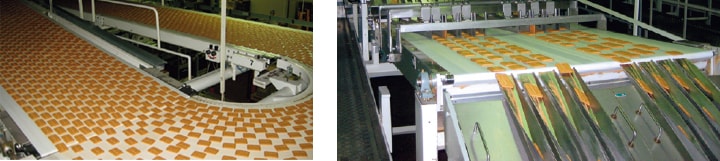

High-Speed Inspection of Broken Biscuits

Nutrition & Santé is Europe’s leading maker of organic and health foods. Biscuits roll off its production lines in stacks of 4 or 5 units that are then wrapped in packs and inserted in their cardboard packaging at high speed.

“For us, broken biscuits are a critical defect. Not only did we want to increase our customers’ perception of the quality of our products, we also wanted to eliminate the risks of packs being incorrectly sealed due to biscuit bits getting in the way,” explains Fabien Ployon, Production Manager at Nutrition & Santé’s production site in Annonay, France.

“We looked at the vision systems on the market and contacted a number of companies. All but KEYENCE declined on account of our speed requirements, which allow a window of just 150 ms for inspecting each stack.”

“We needed a detection solution that could handle the huge quantities of biscuits that are processed each minute and operate round the clock. We installed and programmed the CV-5000 vision system with the assistance of KEYENCE’s technical department. Edge detection is performed by two cameras placed around 20 centimetres above the biscuits on each line. A different program has to be set for each of the thirty-odd shapes and sizes conveyed on each line.”

“Edge detection is just one of the 19 inspection tools available with KEYENCE’s CV-5000 vision systems. Each makes it possible to set up a detection application both simply and quickly. “Despite not having any previous experience in vision systems, the CV-5000 was easy to set up and use. It took a little time to optimise it to our needs, but now we’re familiar with it and we’ve since embarked on a process of continual improvement,” adds Mr Ployon.

This biscuit-inspection application was made possible by the detection speed of KEYENCE’s CV-5000, the most powerful self-contained vision system on the market. For example, it allows 1 million pixels to be processed in 20.5 ms. This processing power also makes it possible to perform multiple inspections and further enhance the reliability of in-process inspections thanks to its unparalleled repeatability (seven times higher than that of current standards) and many image-processing tasks that optimise inspection accuracy. CV-5000 Series models are controlled by a high-speed colour image processing engine and a high-speed RISC (Reduced Instruction Set Computer) CPU. Both are supplemented by two DSPs (Digital Signal Processors) designed specifically for image processing. All CV-5000 Series models use these four processors to achieve parallel processing and attain the fastest processing speed possible – around twice that of the leading models available on the market. The system is also equipped with a double- buffer memory that allows it to accept the next trigger input while an image is being processed.

“Because the CV-5000 vision system works faster than our lines, it gives us definite leeway. It runs seven days a week and we’re very satisfied with its detection reliability and stability,” concludes Mr Ployon.

For more than 30 years, Nutrition & Santé has been guided by the very simple idea that what we eat affects our health. What was held by very few in the past has since become virtually mainstream now that ‘naturally correct’ is ubiquitous. The Nutrition & Santé Group is present in all distribution channels and key organic and health-foods segments. It can count on Gerblé, Isostar, Gerlinéa, Milical, Modifast, Pesoforma, Céréal Bio, Soy and other high-profile brands to increase its exports. These strengths have established the group as a key player in five segments – everyday health foods, nutritional weight-loss products, sports nutrition, organic foods and plant alternatives. In 2011 it employed 1,100 people at its four specialised production sites and operated a distribution network in more than 40 countries, including Japan.

Related Products

-

- Intuitive Vision System

CV-X series -

High Performance, Icon-driven system with easy-to-use tools for simple setup by any user.

- Intuitive Vision System

- PLEASE

CONTACT US