High-speed, High-Accuracy Digital Displacement Inductive Sensor

EX-V series

High-speed, High-Accuracy Digital Displacement Inductive Sensor EX-V series

Impressive Performance with Proven Results

High-accuracy equipment monitoring in any environment.

High-speed, high-accuracy, eddy current sensors with sub-micron resolution and an ultra-fast 40 kHz sampling rate.

Features

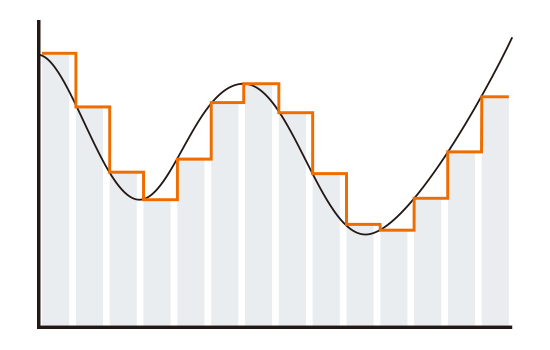

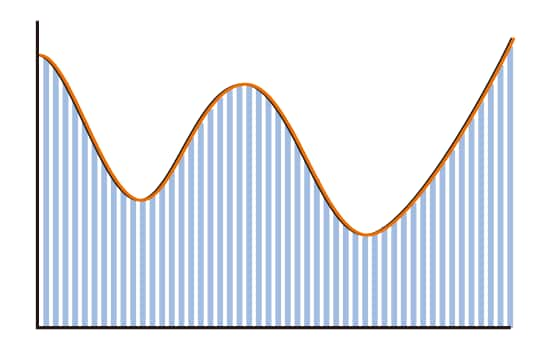

The High-Speed, 40,000 Samples/Second Sampling, Does Not Overlook Any Instantaneous Changes

The EX-V Series combines high-speed sampling with a newly developed linearity correction circuit which results in dramatic performance improvement over conventional eddy current systems.

KEYENCE’s conventional model: 2000/s

EX-V: 40,000/s

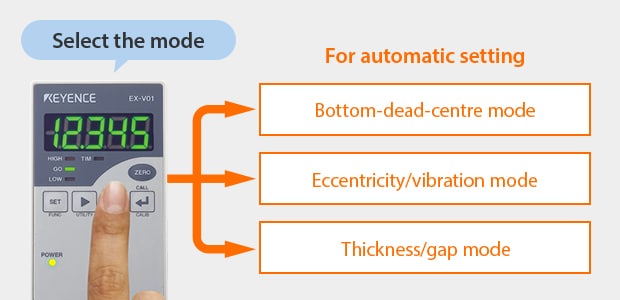

Automatic Configuration of Settings Just by Selecting the Mode

The optimal program for the application is automatically set by just selecting the measurement mode. There is no need for complicated settings of a trigger input, timer setting or arithmetic operation using external devices.

Timer operation or average value calculation can be set at the push of a button on the EX-V digital controller. No PLC or PC is necessary. No external devices are needed for synchronisation.

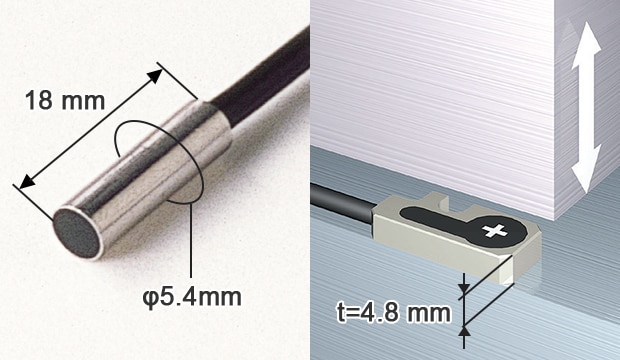

Environment-Resistant Sensor Head

Designed for industrial use almost anywhere, the sensor head is designed to be resistant against harsh environments, to save space and to allow for easy maintenance.

Resistant against harsh environments: IP67 rated

Space saving: Compact or low-profile type available